Heat Exchanger Chemical Cleaning

RYDLYME is the perfect heat exchanger cleaning chemical to circulate and remove mineral deposits from heat exchanger tubes! Heat exchanger cleaning is made easy with RYDLYME Descalcificador biodegradable. Simply circulate RYDLYME through the heat exchanger tubes removing mineral and scale build-up in a safe and timely manner.

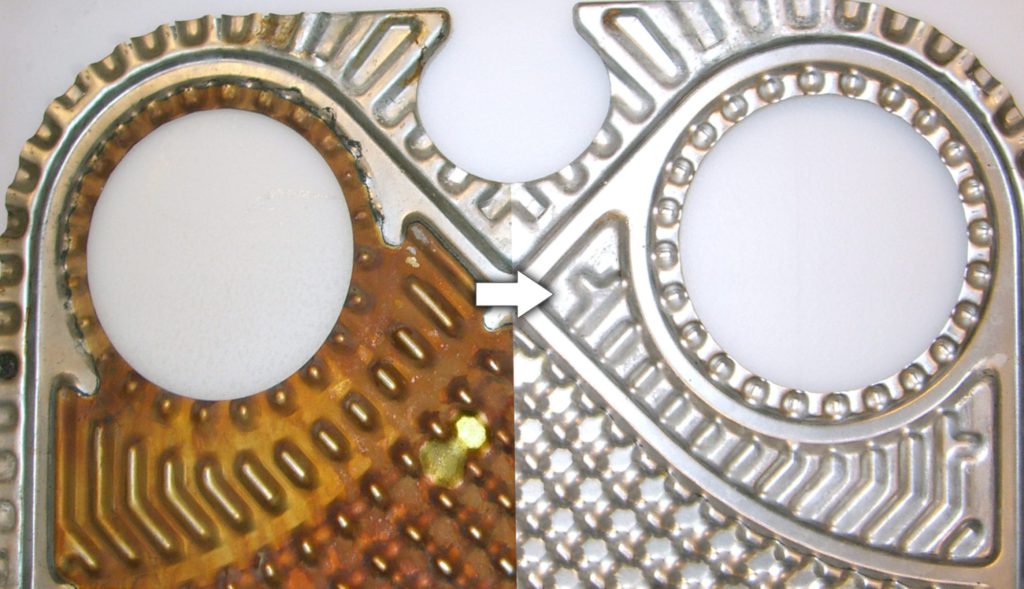

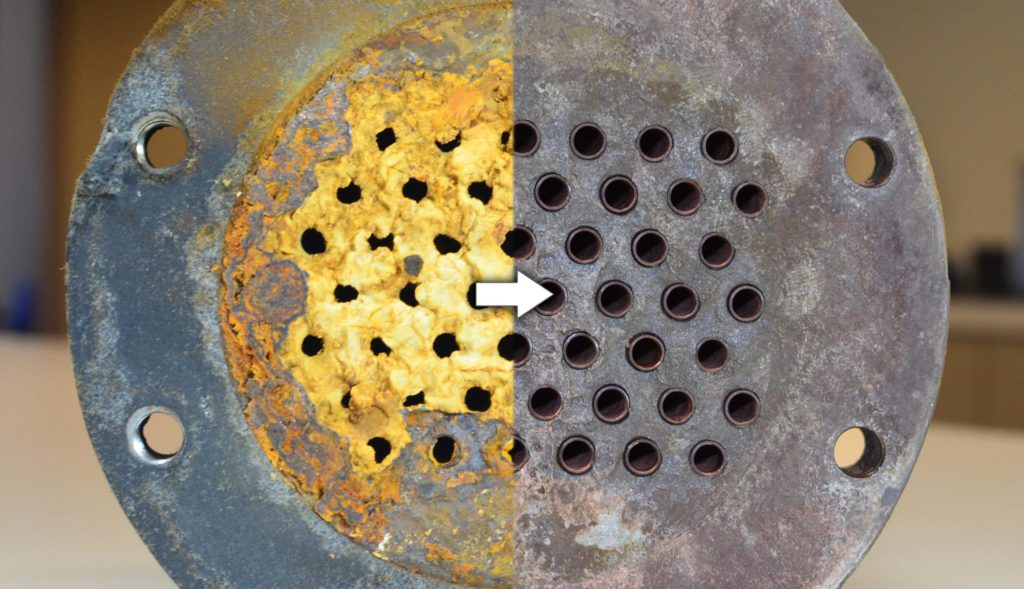

Water scale, lime, mud, and rust deposits are a serious problem for virtually all industries that use water as an integral part of their manufacturing and heating/cooling processes. Equipment or systems with clean water passages operate in a designed and effective manner. Once the water-based equipment or systems become fouled with scale, efficiency decreases, energy costs increase and the useful life of the equipment is diminished. Failure to address water scale problems in a timely manner runs the serious risk of costly equipment or system shutdowns, repairs, or even replacement.

Fortunately, there is a solution! Periodic RYDLYME cleaning will dissolve these deposits into solution restoring efficiency, conserving energy, extending the equipment’s useful life, and reducing the risk of costly repairs, replacement, or plant downtime. Arming your plant and personnel with RYDLYME as an integral part of your preventive or predictive maintenance program will provide you with a weapon that is easy to use, efficient and safe. RYDLYME cleaning allows equipment or systems to be cleaned without labor-intensive dismantling or removal. Some systems can be cleaned on the run and without shut- down. RYDLYME cleaning can be performed by utilizing your own personnel, eliminating costly additional outside expenses. RYDLYME works quickly and efficiently, with most applications completely clean in a matter of hours. RYDLYME is safe enough to hold in your open hand, does not require any neutralizing or pacifying, and is free to rinse with water. RYDLYME has a pleasant odor and does not exude any obnoxious or toxic vapors when dissolving water scale, lime, or rust deposits.

NON-HAZARDOUS & NON-TOXIC WITH NO HEALTH RISK!

The use of RYDLYME does not require special safety equipment or procedures because it is a non-hazardous and non-toxic descaler! There are no toxic fumes and you can even HOLD IT IN YOUR OPEN HAND WITHOUT INJURY! CLICK HERE to see proof! There are NO restrictions, special licenses or permits needed to transport or handle RYDLYME! Review Section 14 Transportation Information of each product’s SDS to learn about restrictions.

What does this mean to you?

The safety of RYDLYME quells any health and safety concerns when it comes to handling and transporting the product. You will have a much easier time introducing RYDLYME into any number of heat exchangers than with hazardous chemical descalers because there is no need for special hazmat equipment (e.g. respirator, suits), elevated temperatures or procedures (e.g. permits, special handling). Review Section 8 Exposure Controls/Personal Protection of each product’s SDS to learn about protection.

For example, an accidental spill at a facility with a container of RYDLYME does not necessitate special hazmat containment and disposal procedures or even poses a safety or health concern to personnel or equipment. It can be safely disposed of down a normal plant sewer or drain, followed by a thorough water flush and clean up is done. The same cannot be said about other descalers. Review Sections 12-13 Ecological Information and Disposal Considerations of each product’s SDS to learn about biodegradability, environmental concerns, and disposal.

Heat Exchanger Cleaning Procedure using RYDLYME:

Our biodegradable and innovative descaler, RYDLYME, is the universal product of choice for heat exchanger scale removal. Besides avoiding heat exchanger failures, with RYDLYME you regain original design heat output, efficiency, and reliability!

Heat Exchanger Cleaning Procedure:

- Isolate and drain the water side of the exchanger to be cleaned.

- Place a 1” ball valve between the isolation valves and the heat exchanger on both the supply and return.

- Attach the RYDLYME pump and hoses so the RYDLYME will be pumped in the bottom or supply, and back out the top or return.

- Begin pumping all the required RYDLYME into the exchanger. Once that is accomplished, begin to add water to complete the circulation. Please note: The calcium deposit will take up volume within the heat exchanger, so you will not be able to add the same amount of water in the beginning.

- Continue circulating the solution for the recommended amount of time. As the circulation progresses and the product dissolves the deposits inside the unit, the volume will increase. To account for the increase in volume, please add water to the circulation vessel, as needed. If you begin adding a lot of water, please be aware, it is possible there is a leak in the system.

- It is a good idea to periodically check the effectiveness of the solution while circulation is in progress. This can be accomplished by utilizing a pH meter and as long as the solution retains a low pH, the product is active. Should the circulating solution reach a pH of 5.5 to 7.0 before the recommended time is up, you will need to add more RYDLYME and possibly extend the circulation time..

- Upon completion of the recommended circulation time, the solution may be purged to a normal sewer and flushed with water. This process is completed by placing the return hose in the drain and adding water to the circulation container until the discharge line runs clear.

- The unit is ready to be returned to service.

- The same instructions may be used for plate and frame-type heat exchangers. For volumes, please follow the noted formula.

Please note: If your situation dictates that you cannot take your heat exchanger off-line, please contact the manufacturer for online cleaning instructions.

For more detailed instructions, call Apex Engineering Products today for a free quote at 630-820-8888 or download our heat exchanger cleaning brochure here!