Boiler Tube Cleaning

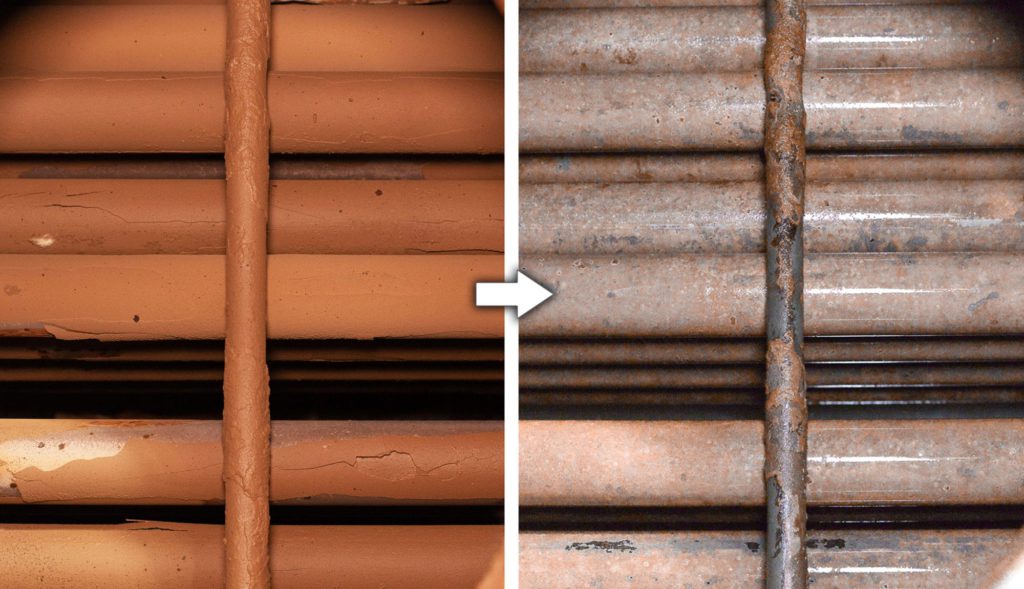

Boiler tube cleaning is made easy with RYDLYME Descalcificador biodegradable due to the chemical’s unique attributes. As RYDLYME is circulated throughout the boiler system, the descaler will remove mineral deposits and clean boiler tubes of scale that dramatically increase your fuel consumption. Please view our boiler tube cleaning brochure for a cost savings chart!

Looking for a Boiler Cleaning Kit?

What is a Boiler?

A boiler is an encased vessel that provides a means for combustion heat to be transferred into water until it becomes heated water or steam. Once the heat has been transferred, the hot water or steam is then usable for transferring the heat to a process. This is a very efficient means for transferring heat for a process, however, over time minerals from feed water deposit onto the heat transfer surface and begin to obstruct the efficiency and increase operating costs.

How Often Should I Perform a Boiler Tube Cleaning?

An annual RYDLYME cleaning of boiler tubes will dissolve and remove the calcium, magnesium, rust, and other deposits into the solution without harming the components within your boiler. Another benefit to cleaning boiler tubes with RYDLYME is that the non-hazardous descaler is safe for personnel who perform the cleaning and can be disposed of down an ordinary drain.

Our descaler is the universal product of choice to clean boiler tubes. Cleaning the boiler tubes (water side) on a regular basis will improve the boiler’s technical and economic performance.

RYDLYME Features:

- Biodegradable

- Dissolves 2.2 lbs of scale per gallon of RYDLYME

- NSF/ANSI 60 certified

- Non-hazardous, non-corrosive and safe for personnel

Boiler Tube Cleaning Procedure:

- Shut down the boiler.

- Blow down with pressure still on.

- Drain and flush the unit.

- Close the steam valve.

- Add RYDLYME descaler, and then top off with water.

- Circulate through the drain or low point and return from the pressure relief valve or high point of the boiler back to a vented container for 4-8 hours depending on volume.

- Open the steam valve.

- Drain, flush, re-fill and start the unit back up.

For more detailed instructions, call Apex Engineering Products today for a free quote at 630-820-8888 or download our boiler cleaning brochure here!

A large pharmaceutical manufacturer was having serious fouling issues within their boiler system which supplies heat for five buildings.

A Midwestern college was noticing heating inefficiencies in their boiler system.